First draft of a book tentatively entitled...."To be an armour maker like me" Please comment freely, this stream of consciousness needs to be corralled.

Part 1....Making the armour! Templates.

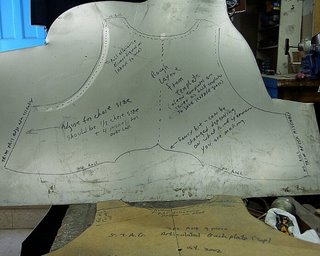

The first step is to develop a template, and then the pattern. This can take a lot longer than you think, and you have to make the piece over and over again, modifying the template every time until you have perfected it. Some of my templates have been modified 8 or 9 times, and I still have not got them right. To make matters worse, each template, after it is made, also has to be sized to the individual. A template sized to an individual is called a "pattern", and each pattern is pretty much disposable. The pattern contains a lot of personal stuff, like the kind of decoration, style of fluting or grooving the client wants, whereas the template is the bedrock design upon which you base the pattern. The artwork is in the pattern. The engineering is in the template.

Changing the template is hard. Changing the pattern is easy. Since most armour is customized to a greater or lesser extent, it is best to change the pattern rather than the underlying template. You can go broke pretty quickly by trying to make armour you have never made before! One time I fell for the line a client spouted.... "yeah, I want you to make the tin man from the Wizard of Oz. How hard can it be...you make much more complicated armours!" True, it was a much easier looking item, and in fact it is. However, it required 3 templates, and when I finally made the item it didn't fit him. "I waited almost a year for a simple costsume that doesn't even fit me! No way I am paying for that!". And lets face it, how could I charge for all that templating work. I was foolish to not break the job into two parts....the development and the production. As it was, I wasted weeks of effort, all a dead loss.

It really helps if the client knows what they want. And that they realize that if I custom build a job it will cost a lot more. A recent helm was heavily customized, and the client suddenly refused to pay for it. Too expensive. "Dude, you agreed to the extra work! Too expensive. I'm going elsewhere. "Fine" I said, I'll keep it here. Two weeks later, another fellow contacted me, wanted a helm customized just like the one I had lying around, and so we made a deal. It was about 30 bucks less than what I was going to charge the first guy, so I took a hit just to move it out of the showroom. (you know where this is going eh?) Turns out they were brothers, and they played this silly game in order to get a cheaper helm! All that hassle for three sawbucks!

They don't know what they want... the dreaded "Well, what does an armour cost"?

I just recently turned down a potentially high profit job....a local engineering firm wanted me to make a hardshell for military EOD armours. (EOD...Explosive Ordinance Disposal. They already wear expensive kevlar suits....this would be an extra shell. I guess every little bit helps!) Their thought was "hey, why re-invent the wheel...there are people who actually MAKE armour...we can just get them to pound some out. Again, price was no object if I could make what they had in mind. Trouble was, they wanted, like, 40 of them. In a month. They didn't know what material would be best....aluminum, steel, or stainless.....they didn't have a template made. I told them it would take a couple of weeks to define the template and make a couple of testers, and another couple of weeks to get the specialized aircraft aluminum delivered. I have no regrets about missing out on such a good contract. They didn't know WHAT they wanted so how on earth could I possibly give a completion date and a price!

1 comment:

I bet that Tin Man costume was gorgeous, though.

Post a Comment