The reason you roll the edge of a piece of armour is so that it doesn't cut into your body. Generally you roll the armour anyplace where it touches the skin. Some exceptions exist, the gorget bib or the shoulder tabs on this backplate for instance, but when you have such an edge, you should line it with leather for simple safety reasons.

Safety is a funny concept. It is closely allied to liability. How much liability does the armourer have? According to my lawyer, anybody who purchases an armour from me has a "reasonable expectation of performance". Same as if he bought a car from me, he expects the engine to start, and the brakes won't suddenly fail on me. People that purchase armour from me expect it to be comfortable, long lasting, and capable of shedding weapons strikes. There is also something called "armour bites", where the armour causes damage to the person underneath, often unrelated to the weapons strikes! My job (among others) is to minimize armour bites. Rolling will help. Designing out 90 degree corners, and making space for underlying leather or padding is also within my perview. On your template, you must leave a half inch "roll allowance".

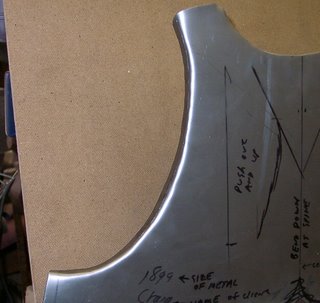

The first step of course is to determine which edges need to be rolled, and push it down over the heel of the anvil until a half inch flange of metal is sticking out all around the edge you want to make safe. Then using your nice shiny ball peen hammer and a big old brick breaking chisel as a mould, you curl the metal around until it it goes from 90 degrees to 180 degrees. It is best to not hit it too hard, or you just flatten it all out. You want it to have a space inside the roll. When I do this job right, I can slip a wire into the space from the end. The guys in the old days used to put a wire into the roll. This wire is called a "bail" and as far as I can see, it serves no useful purpose in heavy armour. When you are done, the edge of the armour should look and feel like the top edge of a metal bucket.

This rolled edge is very sturdy....and will be hard to push around.

3 comments:

You know, for the longest times they wouldn't roll the edges on the chassis of computers.

Because of this, I probably lost whole liters of blood on the inside of many PC's :D.

Nowadays even cheapie cases have edges rolled. Probably because more people are going hands-on with their PC's and they don't want to get sued!

Looking forward to stopping by and pestering you this summer, to see what you have going on!

Metal work is metalwork!

Wow. That is so cool! I had no idea.

Post a Comment